|

|

|

|

|

|

|

2006 Blog (Read bottom up)

12/23/06

Merry X-mas everyone. Well the Payne rod has been dipped and is sitting in the drying box. I'm doing things a bit differently, I'm going to wrap after I dip. We'll see how that goes. The rods didn't turn out as I expected so instead of selling them, I'm going to finish the Payne and them start over.

11/16/06

I'm making good progress on the two X-mas rods. I've got the butt of the 200 planed and will be working on the mids tonight. Best case scenario is that I have the entire rod planed out by Monday night and glued up on Wednesday. Then I could work on the Garrison over Thanksgiving, probably getting a tip and butt on that rod done. We'll see. I think I may be cutting it close for an X-mas delivery.

I've got almost all the components but have decided to change the sequence on my finish work. I'll dip for a week and then start on the wrap, this will add another week or two to my normal time frame.

My friend Erik was over on Saturday. He's a master rod maker and I admit that I was a little embarrassed to show him my prep work. It seems a lot of my flattened nodes had popped out or I simply didn't get them flat enough. I'm having to rework them with dry heat before I plane. Hopefully that doesn't make them brittle.

11/6/06

Still working nodes. Should start roughing by the end of the week.

I was poking around Gino's site and found some cool pictures he took of rod number 5.

11/2/06

Well, I've actually been doing a bit of rod making. I fixed the beveller a couple of weeks ago and am in the process of working the nodes and roughing a Payne 200 and Garrison 201. I have high hopes for the Garrison. If it's as nice as I remember it'll be a great rod.

I never did really get started on Gina's rod. That's going to have to wait until opening day next year.

Last weekend was the Great Western Rod Makers Gathering. It was fun, there were more rods than last year which was nice. Larry Tusoni of High Sierra Rods had a Greenheart rod and several pentas he made. There all cast pretty well. The Greenheart was amazing, it was heavy but felt well balanced in the hand and cast for distance with little effort. My favorite rod was a Garrison 206 made by Robert Kope. He had two rods one with NS ferrules and one with bamboo ferrules. I actually liked the NS ferrule rod best.

In early October I took the Payne 100 3pc on a long backpacking trip. It did ok, it was a nice rod for short line nymphing but didn't handle the heavy nymphs as well as I'd like. I picked up some bark on the trip and am going to try to make a rod with two tips and two mids and use the bark for the handle. Hopefully, I can make a rod which will work as a 7ft and an 8ft by changing the mids and tips. We'll see what happens.

9/13/06

Well I've been fishing pretty hard and not doing any rod work. I'm going to have to get started soon though, I've got to finish 3 rods by X-mas.

I've done some work on the beveller and hopefully I can get it to work. The ferrules on rod #4 and #5 came off. I suspected they might. That hot melt glue simply doesn't work for me as a ferrule glue.

I've been fishing the 97 a lot. The ferrules are working great.

8/8/06

I fished the Payne 97 this weekend and absolutely love it. It's a great light trout rod, much more fun to fish than the Payne 100. I fished dries and nymphs and though I wouldn't call it a nymphing rod, it handled sight nymphing like a trooper. It's definitely on my recommend list for anyone looking for a light trout rod or "small creek" rod.

I've done a little work to try and fix my beveller. I'm going to give it a try on my next few rods.

I spoke to my friend about the rod I'm making her and it seems she likes the color orange, so the wraps will be orange which means the rod will have to be lighter than I'd planned, which means I've got to split up a new culm. I'll do that this week some time. After trading some emails, I decide to make her a Cattanach 7ft 4wt aka the "Sir D Favorite", it's more of an all around rod than the Garrison.

I'll make the Garrison later in the year. I'm more than happy with the Payne 97 anyway.

7/22/06

I'm in the final stretch. The rod's in the dipping chamber. It appears I've got some pruning of the wraps again. I might have to redo those, I'll have to wait and see. I had a little problem protecting the grip from the varnish. It may need a little sanding.

Looks like I start work on the Garrison rods tomorrow.

7/18/06

I'm on the second coat for the wraps and I've started picking out the cane for the Garrisons. Gina, if you're reading this, your rod's next. :)

7/12/06

Well, I couldn't hold out any longer. I did some casting in front of the house and set the stripping guide.

7/11/06

Iíve taken the Payne 97 out nearly every night this week and cast it. Itís not a spectacular rod but has a nice light action that is pleasant. Light, like the Payne 100 but deeper flexing. Iím dying to start wrapping the rod but I havenít been able to get down to the casting ponds to finalize the guide spacing. I used to live 10 min from the ponds so stopping buy wasnít an issue but now I live about 30min on a good day.

I picked up a new rod the other day. My friend Erik sold me his Miyazaki Puyans rods so I can knock that off my list of rods to make. Itís an interesting rod. The ferrules donít seat all the way, they seat like spigot ferrules.

Speaking of ferrules, I fit the ferrules on the 97 before I glued them to the blank. The result was a much easier fit than a usually get but one that is a bit rough. The ferrule feels a bit gritty as it slides in and out. I think this is not a function of the fitting but I blued these ferrules and a little of the bluing solution seeped into the female part of the ferrule.

7/09/06

Well the Payne 97 is the evaluation phase. I turned cork and installed the ferrules this weekend and have the guides taped on and ready to go. I'll head to the casting ponds tomorrow or Tuesday to finalize the guide positions.

I finally figured our a way to straighten the rods. After trying the ironing method and hot plate method, I resorted to the heat gun and a little leverage.

I worked on straightening for 3 days and applied more heat than I thought would be necessary with the two former methods. They weren't getting me anywhere. They both require that you apply a lot of heat, although rather slowly. Time will tell if it's a problem.

7/04/06

Well, quite a bit of promise on all fronts this week.

Firstly, I've glued up the Payne 97 and on my way to the straightening phase. I realized this week that I've been binding my rods incorrectly. That is why the last few rods made with the Garrison Binder haven't been as tight as I like. The butt on the 97 isn't very tight but the tip looks pretty good. I'm also starting to realize how binding affects twists and bends in the rod. If I can send the rod through the binder without twists and bends then I should end up with a relatively trouble free rod.

Secondly, I've finally been given the taper for the elusive Payne 196 rod. I've been told it's straight from Mr. Payne and the maker's had it since 1969. I've also been sword to secrecy. I can make the rod but I can't give out the taper. No problem there. I had come up with my own taper but the taper I was given is much different than I expected. Much softer in the butt. It's definitely not the faster 196 taper I tried at the fishing show a couple of months ago nor is it the taper as described to me by Hal Bacon. It seems that what I keep hearing is true, Mr. Payne at one point seems to have sped his tapers up.

Thirdly, a couple of weeks ago I picked up a new customer, a friend of Gino's and he wants two rods. He's got pretty specific criteria too so it should be pretty fun to make. The nice thing about getting orders for new orders is that it gets me out of my normal mode of rod design. A custom rod allows me to make things a little different than I might normally. I've pegged them as rods 17 & 18.

6/25/06

One spline to go. I'm sick so I doubt I'll get it done soon.

6/22/06

Finished planing the butt section and I'm almost done with the tip. Things are going well so far.

6/11/06

3 Splines down, 9 to go. I've got to start thinking about wrap colors and grip style.

6/11/06

I fixed the guides on the Fubar Rod and took it too Hot Creek with me. It worked fine as did Rod 12. Rod # 12 was quite nice to fish with actually. It makes a very nice light dry fly rod.

I spent Friday night sharpening plane irons. I'm off to set up the forms and start final planing.

5/13/06

Well, two days in one week. What do you know. I heat treated the rod today. Something didn't quite feel right about it though. We'll see what happens. I'm off to LA for a week but next Sunday I'll start final planing. I need to wrap the fubar rod. I'm planning on taking it to Hot Creek in two weeks.

5/11/06 Well, summer's finally coming, the shop is warming and I'm getting back into the grove. I was at a rod makers gathering last weekend. I met a lot of great people, all hobbyist like me. It's funny, this small informal gathering had more folks and rods than the bigger ones. As with every gathering, I came back with a rod that I just have to build. This time it's a Garrison 201, which I think will be the perfect high country rod for my friend Gina. After I finish the Payne 201L, I'll start on Gina's rod. I'd like to have the Payne 200L ready for the July 4th backpacking trip, so I've got to get cranking on the 97.

4/13/06

I'd like to say that I'm in final planing but I'm not even close. I need to rough plane the butt section and then we'll be ready to roll.

I fished the FUBAR rod last weekend. My first fish of the year was a bass. I snagged my line on a barbed wire fence in the pond I was fishing and managed to lose two guides. I'm not sure how that happened, so much for seeing how little finish I can use on my guides. I'll rewrap the guides and finish as usual.

3/18/06

Taking it easy, tying flies. I'll finish up the nodes tomorrow.

2/26/06

Workin' on nodes for the 97.

2/25/06

Andre Puyans' memorial service was today. It was a nice affair. I got to see a few folks I hadn't seen since the school this summer and others I hadn't seen in years. His wife had laid out some of the magazine articles Andy was in, as well as some of his fly patterns, pictures of he and his family and his first fly rod. (A Leonard, it looked like a 3pc 7). It was nice to see what Andy looked like without his beard.

A few people spoke and told stories about how they met Andy, how he had influenced their lives or his Puyanisms, those little one liners that he seemed to have in great supply. At one point, Vita, who didn't know Andy, cried just a tad. She was really touched by what people had to say. On the ride home Vita asked if I had any stories or Puyanisms, which of course I do. Everyone who knew Andy does.

I was tying up some wet flies last week and having a pretty hard time of it. The one Puyansisms that all his fly tying students know to well, "don't take sh** from your materials" kept ringing in my head. I was "taking sh** from my materials" and wishing I'd paid more attention in fly tying class....

2/24/06 PM

I've been thinking a lot about what rods I want to have for summer. I'd really like to have that 7ft version of the Light Line rod ready for the high country. I'd also like to have the Payne 200L ready as well. July 1st is not to far away in terms of rod making time. It's hard for me to tell how long it takes me to make a single rod but I'm betting it's around 6 weeks. If that's the case, then I have to start on the rods soon. I don't have the ferrules for those rods so I'm going to have to knock out the Payne 97 and then start on the LL. It might even be nice to have the LL ready for the Mammoth trip, that is presuming the taper I came up with works.

2/24/06

We'll a dozen rods is kinda of milestone I guess, so I thought I'd recap some of the tapers I've made.

|

|

| Paul Young Midge 6ft 3inch 2pc 4wt | This is a nice, very responsive rod with lots of power. I really enjoy fishing dry flies on small streams with it but its also powerful enough to fish nymphs and to cast 40ft into a high sierra wind. The guys at the casting ponds get a kick out of casting 70ft with such a small rod. |

| Cattanach 7ft 2pc 4wt- AKA "Sir D" or "Sir D Favorite" |

The Sir D rod is a favorite among rod makers and bamboo

fishers. Depending on who you talk to, the "Sir D" can refer to Wayne

Cattanach's original taper or the taper modified by Darryl Hayashida. I made

the original taper. This a great all around rod and a great first rod for someone new to bamboo fly fishing. It's a fast taper but isn't rigid like some fast rods. It has a slight softening in the butt which allows it to be a great roll caster. |

| Cattanach 7ft 3pc 4wt | This is the 3pc version of the Sir D. It has all the characteristics of the 2pc version and doesn't suffer any from the extra ferrule. I've made 3 of these rods. |

| Payne 197 7ft 6inch 3pc 5wt | This is a great rod with a slower action. The rod flexes deep into the butt when casting and is a lot of fun. I didn't get a chance to fish this one before I gave it away. |

| Norwood Light Line 8ft 3inch 3pc 5wt |

I've become friendly with a rod maker named Bob Norwood who

really understands rod design. I told him what I wanted in a rod and he

designed a taper. I named the taper myself and it speaks to the designer,

Mr. Norwood and the characteristics of the rod, which mimic my Sage LL.

The Light Line rod is a powerful, all around 5wt rod. The tip is softish to allow nice close in casting. It tapers to a faster mid and then softens up in the butt to create a very powerful rod that is a joy to fish. I need to tweak and lighten up the butt a bit; but, I've already designed a 7ft 3pc and 2pc 4wt version based on this design. |

| Payne 100 7ft 6inch 2pc 4wt | This is considered by many to be the best taper ever developed. It's has a classic medium action that requires a very positive forward stroke to cast. I've yet to fish it. It's a nice light trout rod but I prefer rods with a little more power. Maybe one day I'll try to modify the taper so that it softens some in the butt. |

| Payne 100 7ft 6inch 3pc 4wt |

This was my attempt to modify the classic Payne 100. I must

say that I found it less than successful. The Payne 100 is a light trout

rod, feels that way and performs as you would expect. It performs well out

to about 40ft.

The 3pc versions though feel as if they should be more powerful but they really aren't and that's disappointing. |

|

2/23/06 I can't say as I've been doing any rod work this week. I've been leaving the 2pc Payne rods in the sun each day to help accelerate the curing processes but that's it. I have been thinking a lot about what the next rods would be. I'd planned to maybe start making a rod for my friend Gina, but I can't get a hold of her to get a clear picture of what she wants. I'd like to make a couple of rods without order components and I have a couple of size 11 Super Z ferrules and some aluminum reel seats lying around. They'd be perfect for a Payne 97 and Payne 76, which is a parabolic 7ft 1 inch rod. The Payne parabolics are supposed to be very demanding rods in terms of casting ability. If your timing is not right the line for all intents and purposes lands as a crumpled mess at your feet. If your timing is right on, they are supposed to be incredible casting rods.

2/18/06

I awoke today to snow on the mountain. We've had snow down to 1,500 feet and its cold, cold, cold. 30s at night and between 60 and 40 degrees during the day, depending on how much cloud cover there is. Suffice it to say, my sinus have gone into over drive and its too cold to work in the shop.

The Fly Fishing Show is in town and I spent the day yesterday cruising the booths. Randy Johnson was there as was R.K. Bolt and Jim Adams, the antique rod dealer. At the Adams both there was, much to my surprise, a Payne 196! I don't remember if I written about it in the blog but I've been looking for the Payne 196 taper for months. I'd heard it was a 3pc version of the Payne 97, which is supposed to be a medium action 7 foot rod with a very pleasant action. To make a long story short, very few of these rods were made, very few people have the taper and no one wanted to give it up.

In any case, I promptly requested to cast the rod and I'm glad I did. The rod isn't like the 97 but more like the 98, which I dislike. It turns out the 195 is more like the 97 and I have the 195 taper. Jim Adams also had the Diamondback bamboo rods and the Elkhorn bamboo rods. The Diamondback rods it seems are based on Leonard Tapers, so I'm sure I'd probably enjoy them, but I didn't get a chance to cast them. The seem fairly well made and would probably make someone a fine first cane rod. The Elkhorn rods though didn't look at all good. They are also based on the Leonard Tapers. I didn't get a chance to cast either.

I also picked up an Elkhorn fly line. What a piece of crap. It probably casts fine on the new graphite rods but with cane it was horrible. The line felt like I was casting a piece of lead. Every time the line would turn over at the end of the cast, it would slam into the ground. I guess that's what happens when you go against your better judgment. I picked up the like to give to the buyer of rod #10. It was cheap so I thought I'd give it a shot. I was a little wary but did it anyway- big mistake. Ironically though, I just learned that Wal-Mart carries the old Air Cel series under the name Crystal River. According to a fellow that knows silk lines very well, these Wal-Mart lines are supposed to be more like silk lines than any other lines out there and they're only 12 buck a piece. I'm going to have to go and give them a try.

Now back to the rods. I've finished Rod 12. I think it came out pretty well, although I'm not sure it's going to see much use. I'm having a little problem with the wrap finish on rod 11. The finish is pruning a bit, that is the outside has hardened but the inside is still soft, causing the wrap to look like a raison. I thought it might get better as it dried but it hasn't. I'm going to have to sand it off and put on another coat.

2/06/06

Rod 10 is with its new owner. It seems the fellow has another friend who wants a rod. I let him know the prices have now gone up, $100 would cover my cost if I was using cheap components but I just can't seem to do that. I'm guessing it probably costs me more like $150 to make each rod. It's funny, when I agreed to make the rods I didn't plan to pitch in a bag and tube but it just seemed like the right thing to do.

2/04/06

I went down to cast the rods today. I wasn't casting particularly well but it I got done what I needed. 9E seemed to like the TT4 line better than the WF4. The two piece rods worked fine. The step down ferruled rod was the better caster. I'm not sure I've made a real decision on what's best, step down or normal ferrules. The steps downs are easier to lap but they seem to always have some sort of soldering flux inside, which make's them hard to fit.

Overall though, the rods turned out fine. Not my particular cup of tea but good dry fly rods. The rods cast well and roll cast ok out to 40 ft. Beyond 40 ft I think your pushing it a bit. The rods don't bend enough in the butt for my taste but that's why I'm making them. To evaluate each of the Payne rods before moving on. So far I like the 197 the best and if I can make a 200L like the one I cast at the gathering, that will be another rod I like.

Another thing, I think I need to start making my grips a bit smaller or perhaps a bit longer. My hands started to cramp a little while casting.

2/02/06

I LIKE IT! I took number 10 out for a test cast today. Very Nice! I made the right decision by only dipping it twice. 3 or 4 coats on the wraps, 2 dips and another coat on the wraps and the rod seems to have lost none of it's action. If anything, it's a bit crisper due to the wraps. 9E on the other hand seems a bit dead in comparison. There's definitely a difference; especially since 9 was the better casting rod before finishing.

I'm still not happy with the reel seat on 10. I think I may try to whip up another seat this weekend.

I also took rod 11 out to cast. It's nice. The action is a bit slower and fuller than the 3 piece. I'll take 11 and 12 down to the casting ponds this weekend.

2/01/06

9E is done. Vita really likes the finish. I think that the last coat of varnish went on pretty thick. I've taken the rod our to cast and it isn't quite the same rod I remembered. 10E is done as well. I chose only to put 2 coats of varnish on. I think I'm going to put another coat on the wraps. They still look a bit uncovered.

1/29/06

I started dipping 9E yesterday. I let the varnish warn up for 3 or 4hrs and dipped away. It looks like it worked pretty well. 11F has been given it's first coat of varnish and the tip of 12F has been given a coat as well. I'll turn the cork on 12F before dipping 9E again.

I don't think I mentioned it but after a year of waiting, I finally got my cork order last week. I don't think what I got is exactly what I ordered but for .65 cents a piece I can't complain. The cork is pretty good and I got some quarter inch cork that I'm going to use as a grip for 12F. |

|

|

1/26/06

Well, it's been a pretty good week. Rod 9E is sitting in the dipping box with it's last coat of varnish. It was a good learning experience. The rod seems to gather much more dust dipping than it does when I hand wipe. I think it has something to do with the heat of the light creating a convection current of sorts, which draws dust into the box which isn't air tight yet. I've got a couple of ideas of how to improve this.

The one thing that dipping does is bring out all the imperfections. I can see where I didn't sand the blank fully and where I didn't burnish the wraps.

I wasn't as diligent with this rod as I was with the others and you can tell. I'll let it dry for a few days and then try to polish out some of the imperfections. |

|

| Rods 11F and 12F are almost ready to wrap. I've installed the handle cork on 11 and am waiting for it to dry and I've installed a pre-fab grip on rod 12. Both rods are ferruled. The down side of making 4 rods at once is that I don't have enough drying space. Rod 10 is sitting in the drying box, ready to be dipped but I can't fit 11 and 12. | |

|

|

|

|

I won't get much done this weekend but hopefully by this

time next week I'll have rod 10 dipped and rods 11 and 12 wrapped. I

really want to finish 12 so I can send it to my brother-in-law. 9 and 11

are mine. Since 9 is a "blem" for lack of a better word, I'll probably

fish it once this year to give it a test and then send it off to my

parents so I have a cane rod to fish with when I'm there.

|

|

|

1/19/06

Iíve been real eager to start dipping but havenít done so because my shop is pretty dusty. The plan is to blow the dust around in the shop and then turn my shop filter on high and scoop it all up. Well, last night I noticed that the dip tube had some saw dust in it and I tried to clean it out using denatured alcohol. Big mistake, the tube cracked right down the center. I called Tap Plastics up to ask if the same thing would happen with varnish and they said that over time itís pretty likely. Iím glad I discovered this now.

The guy said that I might give polycarbonate a try but for the cost I might as well use copper piping. I had originally planned to use copper but it at $45.00 for 4 feet it seemed cost prohibitive. Well, If I end up going with the polycarbonate, I will have spent $54.00 on plastic with no guarantee of having problems in the future.

On the up side, I scraped rod number 11 (AKA JL3-11F- 7642 or 11F) last night. It came out pretty good except that the butts are still coming out too big. The further down the butt you go, the more itís off. I donít quite understand it. Most of the stations are ok but the last 3 are .006 off. I can take .002 of each side and not be too concerned but Iíd rather not. I need to figure out whatís going on. Itís got to be the glue. 01/17/06 I got a bit done this weekend. I finished the dip tube. Iím pretty happy with the way it came out. I need to get a light for the bottom portion and maybe install some latches for the door.

|

|

|

|

|

|

|

|

|

I also put a second coat of Varathane 900 on rod #10 (AKA: JL3-10E-7643). I much prefer the V900 on the wraps. On the other rod (JL3-9E-7643) I put a first wrap of V900 and a second wrap of diluted Epifanes. The first coat of V900 didnít saturate all the fibers and when I put on the coat of Epifanes, the wraps darkened a bit. The Epifanes also gives it a hard, crusty look. Itís a good rod finish but not a good wrap finish. Itíll be interesting to see what happens when I dip the rod.

I picked up a new shop vac at Home Depot. The shop vac I have is ok but it doesnít have a HEPA filter and all the fine rod and wood dust kept getting blown back into the air. Itís everywhere.

The new vac has a 6.5HP engine and is a vac and blower. Itís much more powerful than my old 1.5HP vac and Home Depot has the HEPA filters readily available.

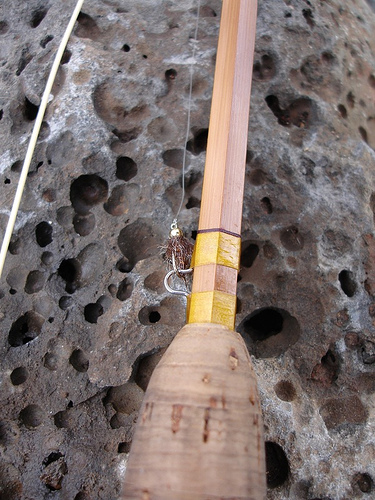

01/13/06 Well, I haven't done any work this week. My parents came for an extended visit and I spent as much time with them as possible. My Dad might normally hang out in the shop with me but in winter the shop's too cold for that. This weekend is a 3 day weekend and I should get a lot done. The ISE show has come to town. Last year was a dud but this year was a bit better. Chuck and Larry were there with their High Sierra Rod Company. Business is good and the rods seem popular. I cast their most popular model the Brookie. It was a nice rod. It roll cast well and was very nice at short distances, which is what it is developed for. I also cast the Tournament model which was a taper that Larry's dad came up with. Larry is a second generation rod maker. 01/08/06 I've finished wrapping the 2nd 3pc rod and have started to make the dipping tube. I should have a workable tube by Tuesday or Wednesday night. 01/02/06 I glued the two piece rods up on Saturday. Everything went pretty well. I'll scrape them tomorrow. I've finished the wraps on the first 3pc rod. I've given the wraps a thin coat of varathane 900 to act as a sealer/color preserver. I'll probably start on the dipping chamber later in the week. I need to go down to Tap Plastics to see if I can get a clear plastic tube. Here's rod 9 sitting on the wrapper before I put a coat of finish on the wraps.

|

|